No matter whether it’s groundwater, contaminated or aggressive media, or unusual operating conditions. Pressure sensors which resistively record the change in pressure (resistance change) are often used in the field of hydrostatics. Generally speaking, these pressure sensors have a stainless steel membrane that is only a few micrometres thick. However, its use in many applications is restricted as a result, since the stainless steel membrane can become damaged by solids within the fluid or through careless, tactile cleaning processes, causing the measurement technology to fail.

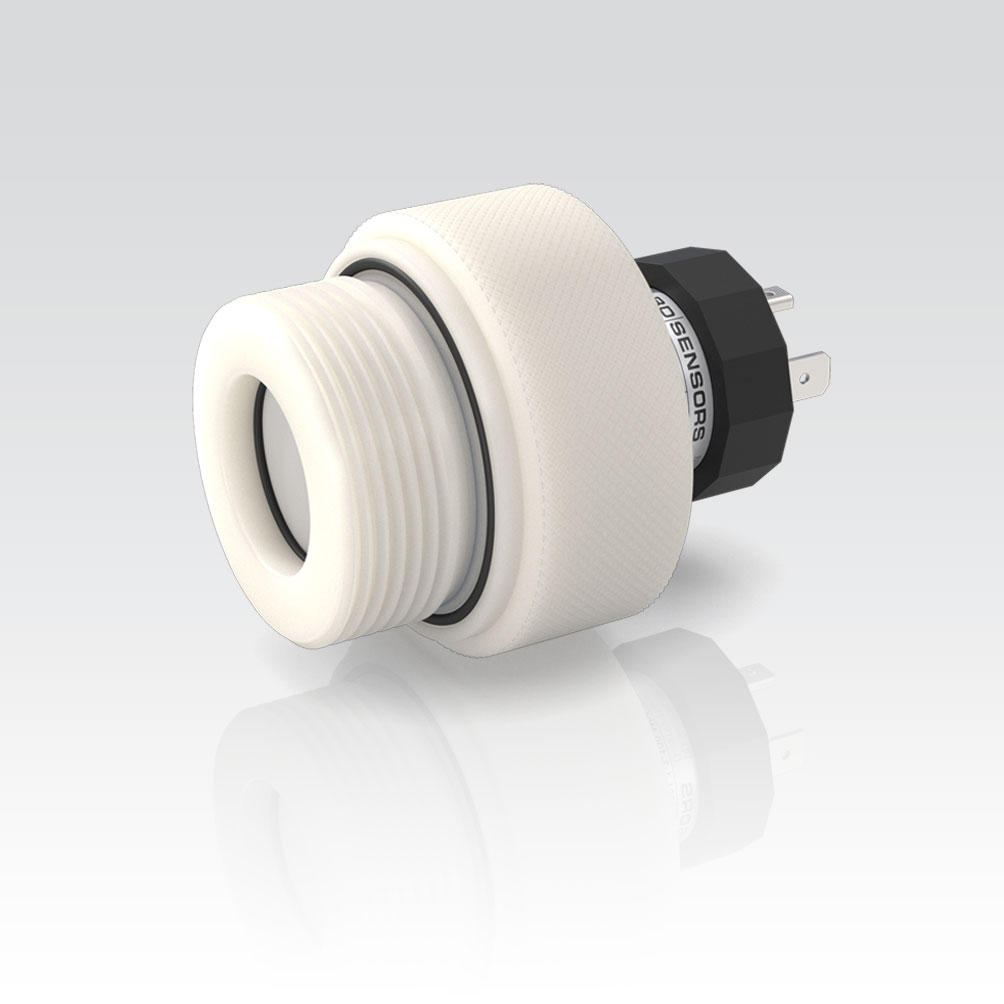

Ceramic pressure sensor with capacitive measuring principle

BD|SENSORS is taking a different approach with these applications or conditions by using a ceramic pressure sensor that was developed specifically for this purpose. As a tool in contact with the medium, the highly pure ceramic and capacitive measurement principle (capacity change) are what sets it apart from conventional pressure sensors. This means that two parallel ceramic surfaces form a plate capacitor, and the pressure change is measured by using a change in the electrical capacity.

The advantages of this are clear: using a high-purity ceramic (99.9% pure ceramic substrate), creates a pressure sensor that is both extremely resilient and chemically resistant, so it can be used in water applications as well as in waste water and chemical or biogas plants. The robust construction of these sensors means that corrosion caused by aggressive media or “careless” servicing actions can largely be avoided. Furthermore, they offer a high level of overload capacity and can withstand possible pressure pulsations. Despite its mechanic robustness, this ceramic pressure sensor is extremely precise with high measuring sensitivity. This means that even very low filling heights (starting from 20 cm, for example) can be recorded reliably and accurately. All this is rounded off by the fact that the capacitive ceramic pressure sensor provides either an analogue or a digital output signal with which different analogue or digital interfaces can be implemented.

Daily use in practice

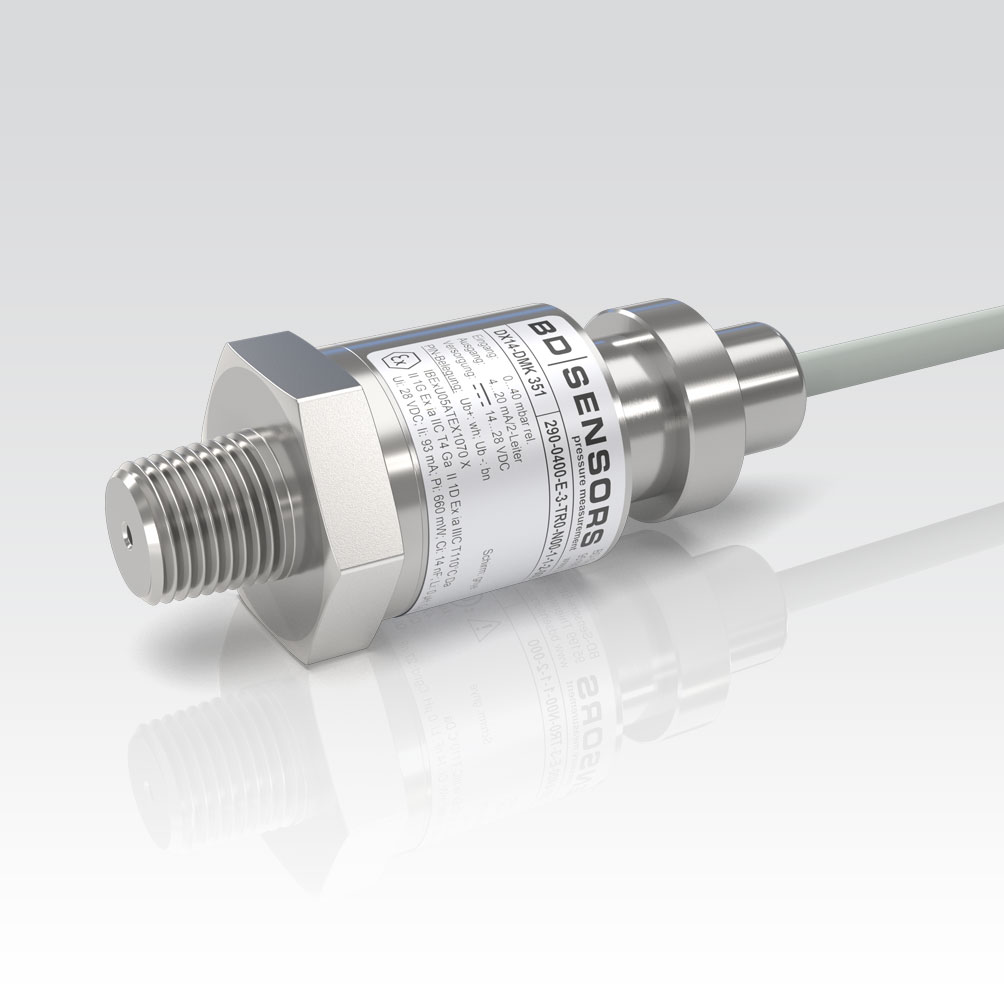

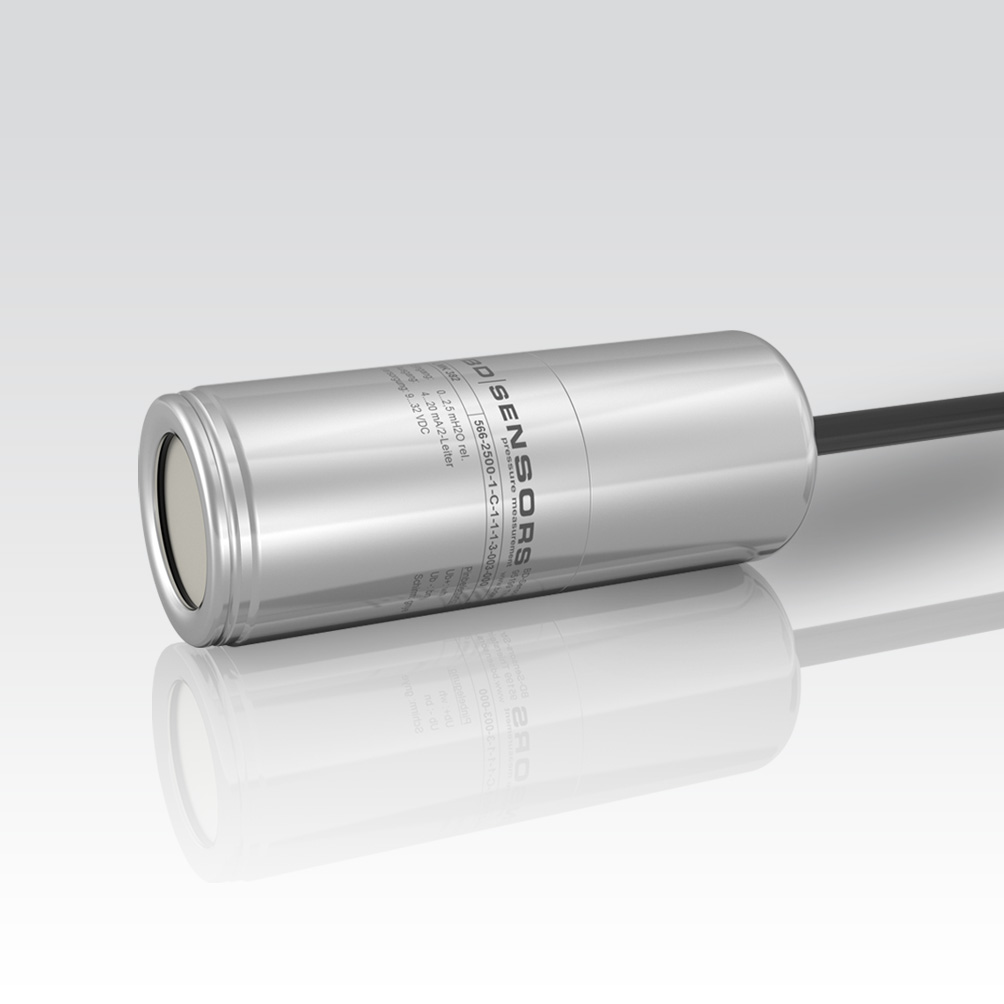

BD|SENSORS uses the above-mentioned advantages of the capacitive ceramic pressure sensor in various products. Depending on the task, the devices can be screwed onto a container or pipe (DMK 351, LMK 351) or else hung in a tank (LMK 382, LMK 809).

![bds_Füllstandsmessung_Befestigung [Translate to englisch:] Füllstandsmessung - Prinzip](/fileadmin/user_upload/Aktuelles/2023/FSM_Prinzip.jpg)