GLOSSARY OF TECHNICAL TERMS

Find hereafter a useful glossary of technical terms on the subject of pressure measurement.

You have questions?

Please contact:

Mr. R. Kottus

Mr. A. Möckel

Team Sales

Tel. +49(0)9235 / 9811-0

-

absolute pressure

In rare cases it can prove necessary to measure the - physical - pressure in absolute terms (e.g. in closed systems). The sensors used in such cases must be specially encapsulated, however.

-

conversion factor

1 mbar = 100 Pa

1 bar = 14,5 PSI

1 PSI = 68,95 mbar -

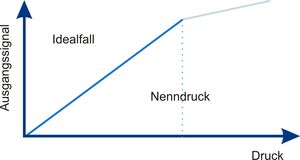

characteristic curve

The relationship between measured value and the output value is described by the characteristic curve. This is ideally a straight line.

-

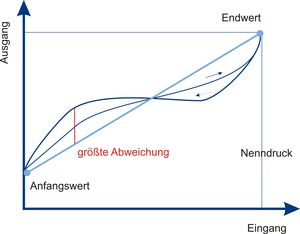

deviation of characteristic curve

hysteresis

The hysteresis is the difference of the output value for a fixed measured value under increasing or decreasing pressure.deviation from the linear

The devation from the linear is the amount of deviation from the characteristic curve of a reference line.

reproducibility

The reproducibility defines the largest deviation from the characteristic curve of a reference line.temperature error

The temperature error shows the maximum deviation of the characteristic curve from the ideal case - for measurements taken at different temperatures - within the compensated sector. The temperature error is normally given as a value applicable to the entire compensated sector and not per 10K or 1K. Deviation of the characteristic curve in accordance with IEC 60770. This value defines the maximum overall error in accordance with IEC 60770, composed of non-linearity, hysteresis and reproducibility in keeping with the boundary setting, i.e. the deviation of the initial and final values from the straight line. As compared with the initial vaule setting or BFSL (best fit straight line), this definition gives the largest characteristic-curve deviation, but it is the easiest method for the user to understand. When accuracy details are given in data sheets, therefore, the error definition must also be specified.

-

initial value (offset)

The lowest measured value to which the measuring device has been collimated. e.g.: 20 mA

-

differential pressure

Differential pressure is the difference between two pressures to be measured.

-

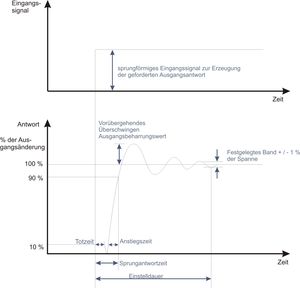

response time

The response time describes (act. to DIN EN 61298 and DIN EN 60770) the period between the start of the step response time and the time for the output to reach and remain within 1% of output span of its steady value. The step corresponding to 80% of output signal, giving an output change from 10% to 90%, then another from 90% to 10%.

Synonymical (in the standards DIN EN 61298 and DIN EN 60770) it can be used the definitions response time and settling period.

-

final value (full scale)

The highest measured value to which the measuring device has been collimated. e.g.: 20 mA

-

electronic pressure switch

Electronic pressure switches have an important role to play when it comes to monitoring procedural and industrial processes. They are used wherever the pressure of a gas or fluid such as air, water or oil must not exceed or fall short of specific values. If a critical change in pressure does occur, a corresponding switching contact is opened or closed to prevent malfunctions or even damage to pumps, valves or compressors, for example.

An electronic switch is constructed in such a way that applied media pressure (in bar or mbar) is converted into an electrical signal (in V or mA) by means of an electronic pressure sensor. Electronic pressure switches offer several advantages over mechanical versions. Not only do they offer a high degree of reliability and long-term stability with switching cycles exceeding 100 million, they also guarantee extremely long utilisation times. Furthermore, they permanently offer highly precise switching in terms of switching accuracy and hysteresis. Switching and reset points, switching outputs and switching functions can be individually adjusted so that electronic pressure switches can be flexibly adapted to the specific demands of each application. In addition, the settings can be shown on a digital display, enabling changes and adjustments to be made during operation.

Electronic pressure switches can be used in a very wide range of applications. This ranges from mechanical and plant engineering (especially pneumatic systems, hydraulic aggregates and machine tools) to environmental technology, medical technology and the food industry as well as the areas of heating, ventilation and air conditioning systems. A critical factor here is also the state of the medium, which can sometimes be viscous, pasty or even highly contaminated. Depending on the requirement and application, various types of electronic pressure switches are available. They vary in terms of their housing types and connection options as well as internal properties such as membranes, accuracies or signal processing. Those models that have an IO-Link interface are especially suitable for exchanging process data, diagnostic and status messages with a higher-level control system.

Product range electronic pressure switch Product brochure electronic pressure switch

-

accuracy

The actual permissible extent of deviation from the ideal characteristic curve is specified in terms of accuracy.

"FS" = Full Scale = final value (e.g. 20 mA)

"FSO" = Full Scale Output = span (e.g. 16 mA)The accuracy specifications are always given as a percentage of the range of measurement (FSO).

-

hydrostatic level measurement

The pressure exerted at a particular depth of a given fluid above the position in question. For water, which has a density of 1 g/cm³, the pressure increases by around 100 mbar per metre of water depth. By calibratingon the basis of the density applicable for the fluid in question, the output signal of a hydrostatic level probe can be adjusted to the depth of fluid to be measured.

-

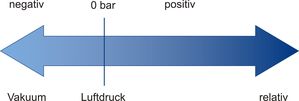

relative pressure

Normally the pressure is measured relative to the prevailing air pressure, i.e. the air pressure corresponds to 0 bar. For pressures greater than the air pressure, positive values (overpressure) are obtained. For pressures smaller than the air pressure, negative values (negative pressure) are obtained.

-

types of sensors

Piezoresistive silicon sensors

non-encapsulated for gases and dilute, non-aggressive fluids with stainless steel membrane for standard industrial applications

stainless steel thin film sensors

for hydraulics applications and high dynamic pressure loadthick film ceramic sensors

for aggressice environmentscapacitive ceramic sensors

for aggressive environments and very small ranges of measurements -

range / full scale output (FSO)

The algebraic difference between final value and initial value e.g.: 20mA-4mA=16mA